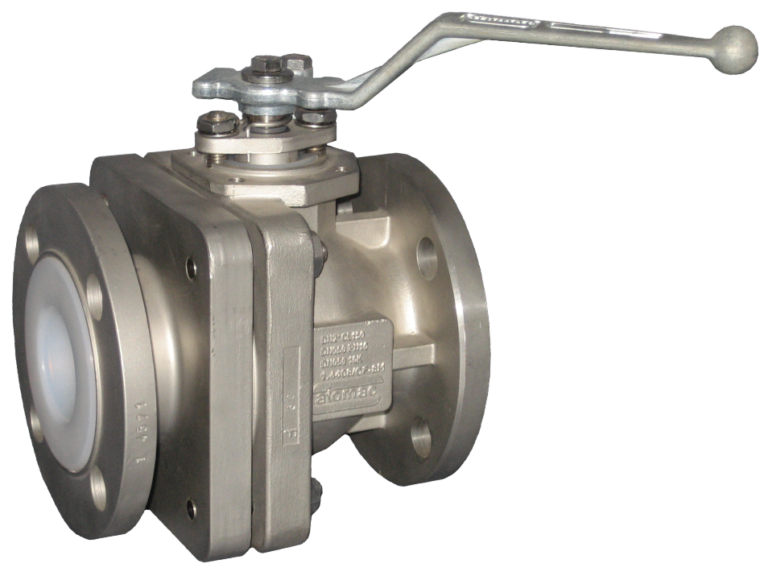

Atostar AS3 Full Bore Short Pattern Ball Valve

The Atostar AS3 ball valve encompasses all of the features and benefits of the AKH2A valve but with a 316 Stainless Steel body. Produced to service the pharmaceutical and semiconductor industries it has many uses, in final production areas, areas of high environmental corrosion etc. One of our customers have adopted this valve where they have a lot of plant strip downs and verifications and were having problems with paint chips contaminating the next batch, using these valves alongside our PTFE lined stainless steel piping completely resolved this costly problem for them.

Installation, Maintenance and General Guidance PDF

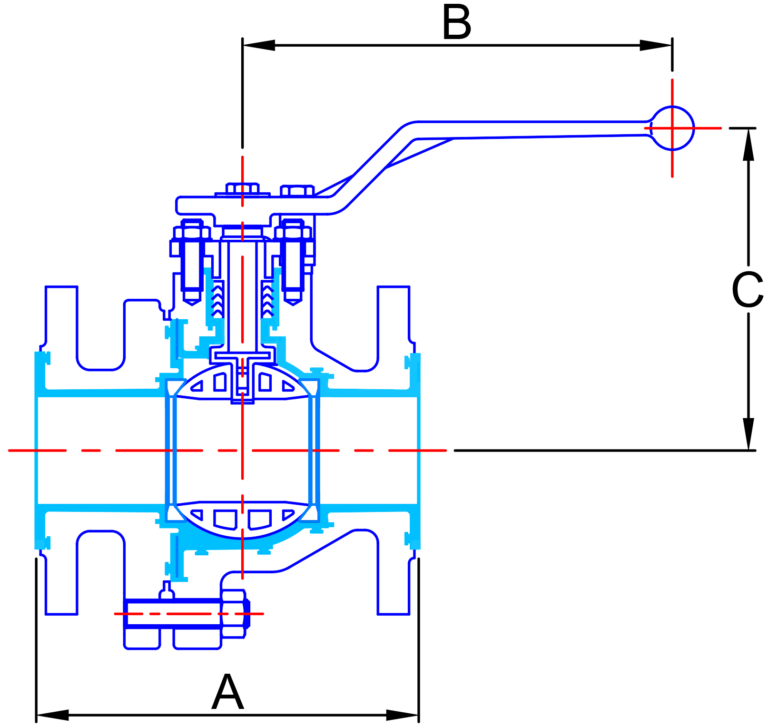

Dimensions To Suit ASME 150 Piping Systems

| To Suit Pipework NB | Face – Face A | CL to end of wrench B | CL to top of wrench C | |

| Inches | mm | mm | mm | mm |

| 1/2″ | 15 | 130 | 160 | 120 |

| 3/4″ | 20 | 150 | 160 | 120 |

| 1″ | 25 | 127 | 160 | 120 |

| 1.1/2″ | 40 | 165 | 210 | 145 |

| 2″ | 50 | 178 | 210 | 160 |

| 3″ | 80 | 203 | 313 | 205 |

| 4″ | 100 | 229 | 313 | 220 |

| 6″ | 150 | 267 | 673 | 300 |

The AS3 has many features that make it one of the best lined ball valves in the world. Stainless steel fasteners and body ensure long term protection from external corrosion. There is no need for any painting so no flakes or chips can contaminate any processes, especially useful when cleaning down components between campaigns.

When used in conjunction with our range of PTFE / PFA lined stainless steel piping systems gives a complete easily cleanable, externally corrosion resistant, aesthetically pleasing piping system.

The AS3 has Cavity filled seats ensure minimum product hold up. T slots machined in to the cast body ensure the PFA liner is secured making it suitable for operation in vacuum conditions. The floating ball offers low turning torques and low pressure positive bubble tight sealing. The seats, ball, stem and stem packing all easily replaceable on site allowing easy maintenance and overhaul.

| Size | Stocked Quantity |

|---|---|

| 1/2" | 0 |

| 3/4" | 2 |

| 1".1/2" | 0 |

| 3" | 0 |