Introduction to Sampling

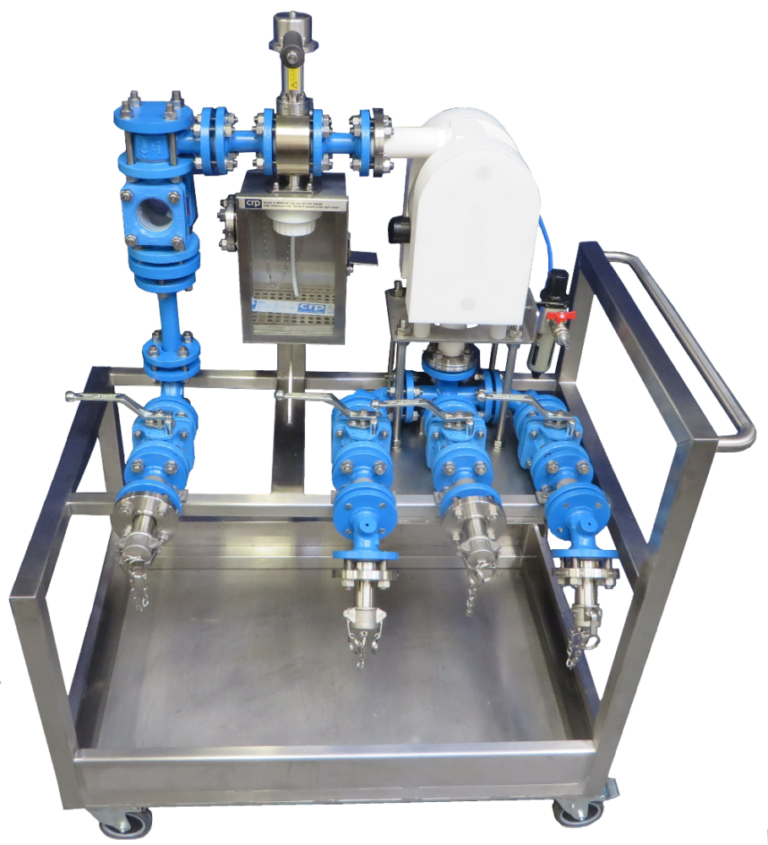

CRP manufacture sampling valves and sampling systems for use in Chemical, pharmaceutical, biotechnology, pulp and paper, mining, petrochemical and semiconductor industries. We produce samplers to collect representative samples from liquids, gasses and powders. Along with stainless steel samplers we can also provide solutions for toxic and very corrosive medias, we supply PFA lined samplers which are designed for sampling aggressive acids such as Hydrochloric, Nitric and Hydrofluoric acids. Safety is paramount and where previously operators were put at risk by collecting samples our systems reduce these significantly.

What is “Representative Sampling”?

A sample taken from a process pipeline or reactor must truly represent the exact constituents of the process without any contamination. Contamination of a sample can create incorrect test results and cause further process problems. Contamination of samples can be caused through reaction with the environment, but is more often caused by traces of the previous sample being held up within the sampling system. CRP’s range of samplers have several design features built in to overcome contamination problems and ensure that there is no pre-running and wastage of any product.

Benefits

Traditional methods of sample taking have been rather crude and rudimentary. They have included open ended valves which have been allowed to flow into effluent drains to run clear any old product before flowing representative enough to take a sample. Or taking a first sample and discarding it before a second representative sample is taken. These traditional methods incur a lot of costs if the product being sampled is valuable and also with the cost of removing the waste and can be especially environmentally unfriendly. Operator exposure is of great importance too and may require the use of expensive safety equipment and personal protective equipment. By using the appropriate sampling equipment designed specifically for the task the operator need only take the volume of sample required to carry out their tests, typically this can be only a few millilitres. Meaning far less spent sample media waste and less exposure to the operator.

Environment

The costs involved in treating effluent and disposing of excess sample volumes is becoming increasingly more expensive. Government legislation is more restrictive and greater emphasis than ever is being placed on the environment. Taking just enough sample volume as required saves in these expensive reprocessing costs. CRP also offers various levels of containment for our sampling systems to reduce and prevent spillages and pollution from the sampling process.

Operator Safety

Taking process samples comes with many types of potential hazard to the operator; Samples can be very hot, corrosive or toxic or all three. The operator must not be exposed to these dangers. We can offer sampling solutions to effectively protect the operator from these hazards. This can often mean that expensive safety equipment and personal protection equipment such as breathing apparatus etc. which can take a long time to put on and use are no longer necessary.

Sample media cost savings

In today’s modern pharmaceutical world manufacturing processes can be extremely expensive with a few grams of process media costing several thousand pounds to create. Likewise, within the fine metal reprocessing industry for example a few millilitres of sample can be worth a significant amount. It is very beneficial to take a very small representative sample from these processes to save wastage costs.

Conclusion

Where process samples are required, it is best practise to specify sampling equipment designed to do this with operator safety, ease of use and cost effectiveness incorporated into the equipment.