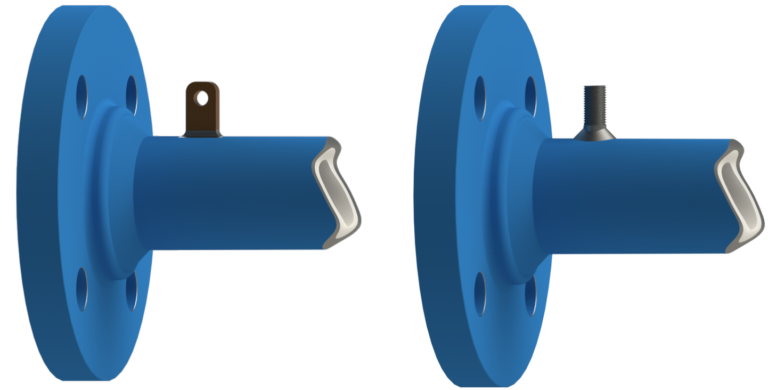

Earth Studs/Lugs

We can help with the earthing of our PTFE lined piping by supplying earth studs or earth lugs directly welded to the steel housings. These can be to a customer’s specification but are typically M6 x 20 copper plated earth studs. For the system to be effective each loose / rotating part must carry its own welded stud / lug. For spools under 500mm long it is usual for there to be just one earth connection in the centre. For longer lengths there is usually one stud / lug located just back from the flanges at each end. With a spool with one fixed and one rotating flange there would be 3 studs required, one at each end of the pipe section and one on the back of the rotating flange. If a cross were to be supplied with all the flanges rotating then a total of 5 earthing studs would be required to ensure that each separate steel element had a stud welded to it. Lugs and studs are electrically connected together with bonding links. This means that the plant can soon begin to look untidy with studs and earth cables everywhere. CRP recommend a different approach to earthing, requiring limited amounts of earth bond jumper cables and providing a much neater and quicker install using Spikey earth continuity washers sized to suit the piping and star washers.