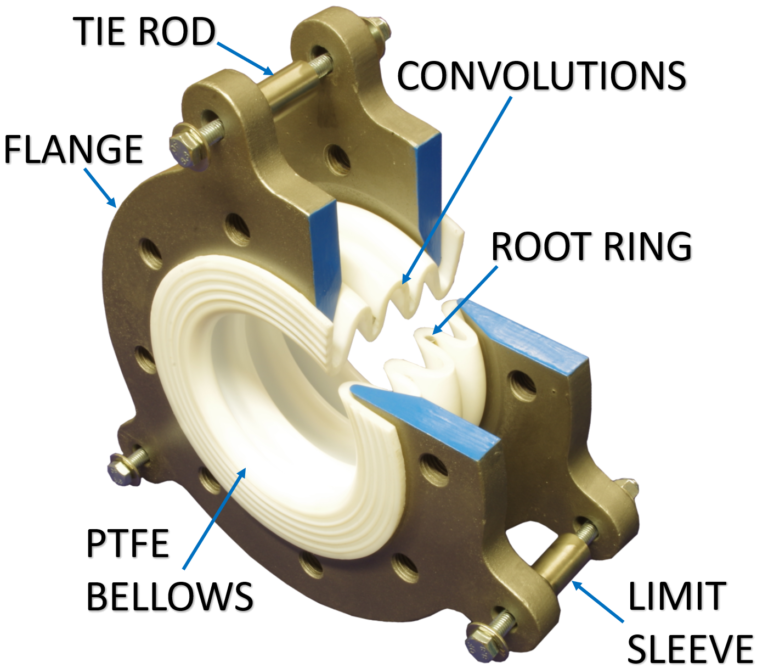

Key Features

PTFE Convolutions

FluoroFlow Bellows from CRP provide stress free formed convolutions with a uniform wall thickness. The number of convolutions is key to the range of movement provided by the bellows. However both pressure and vacuum performance are reduced as the number of convolutions increases.

Flanges

Bellows flanges are available to all of the international piping standards including ASME Class 150 and 300 and DIN PN 6, 10 and 16. As standard the flange connection drillings are drilled and tapped either UNC for ASME or Metric for DIN. Flanges are painted in an ultra high temperature paint in a silver finish. It is worth noting the internal flange profiling that assists the first convolution in minimising any stress generated by the flange.

Root Rings

Root rings serve to provide support for the PTFE which is a mechanically weak material especially when hot. These sit at the base of each convolution. As a standard, our root rings come x-ray tested in high grade stainless steel (1.4571/316Ti).

Tie Rods

These prevent the bellows from exceeding their maximum allowed movements. They arrive factory set at the maximum allowable extension as detailed on the data label – Ready To Install. The Tie Rods on CRP Bellows are designed & strong enough to absorb the forces from the full pressure thrust.

Limit Sleeves

Are standard for CRP and prevent damage to the convolutions by preventing the bellows from being compressed below the minimum allowable axial length..

Data Labels

Also on data labels the CRP bellows give the best example in the market. There are three or four data labels present on the bellows flanges to carry as much information about the bellows as practical. However, more information is available in our catalogue, or by reference to CRP, quoting the part number and serial number references.