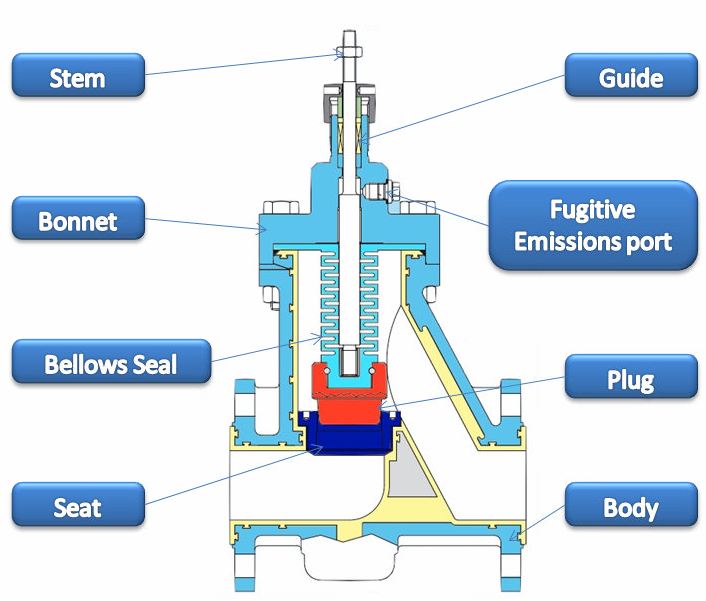

Kammer Control Valves – Key Components

The Kammer control valve is linear in operation based on globe valve principles where the spindle is lifted or lowered on to the seat to allow more or less flow.

The valve size range starts at DN15 / ½”NB up to DN150 / 6”NB and is available with DIN PN 10/16 or ASME 150 flanges.

The stainless steel stem connects to the diaphragm actuator and has an integral blow out proof design.

The bonnet is mounted and compresses the PFA lining and the modified PTFE bellows to form a seal, however it has been carefully engineered so that it finally mounts tight against the body as metal to metal so that there is no remaining play between the two providing a robust actuator mounting platform.

The body is PFA lined ductile iron grade GGG 40.3 equivalent to ASTM A395, providing the best all round corrosion resistance and is protected with a 2 pack epoxy primer in blue.

The seat and plug are screwed in place and can be interchanged to provide different flow rates or characteristics. They are manufactured from modified PTFE or Hastelloy material depening on the flow requirements.