Introduction to Field Flare Piping

Field flaring is a method by which finished pipe spools can be manufactured to length on site. In most cases this method is used for producing emergency spools in the case of a plant breakdown or for the convenience of small scale maintenance. It may also be used to produce the final “closing” spools for project work. Occasionally sites use it as a preferred method for producing all of their spools, usually for historic reasons or a geographic need to be very self-sufficient.

Before choosing to adopt field flaring as a site practice it is important to be aware of the downside of this. First, it is likely that the field manufactured spools are more expensive than factory finished spools. This is because the site work can never be as efficient as factory production and there is more materials wastage. Secondly, the spools are not produced in a clean controlled factory environment with the level of process control that the factory can provide, nor can the traceability of materials be maintained easily. Finally, the field flare is only as good as the operator and the equipment he is working with. Having said this, it can still be a very useful method to have available. Standard sizes for field flare are 1in to 6in.

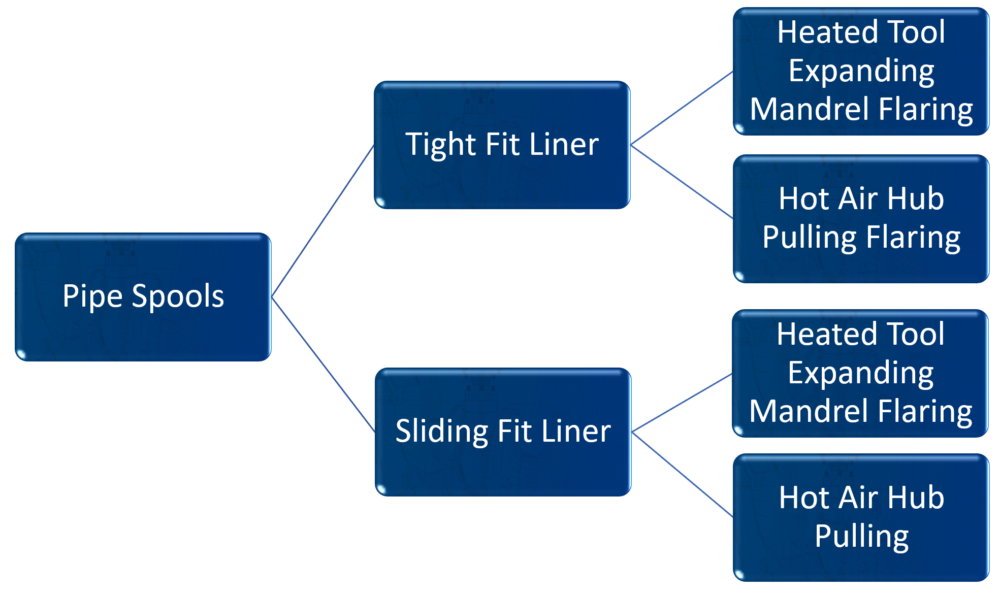

There are a number of method choices with advantages and disadvantages, which are diagrammatically shown below.

Spool Types

There are essentially two types of pipe spool that can be used for field flaring. These are a tight fit liner system and a sliding fit liner system. These choices have arisen from historic manufacturers specifications and tend to be customer site specific driven by their lined piping vendors. If you are new to field flaring, then you can make your own choices and the notes below will indicate the pro’s and con’s for each system and the flaring methods.

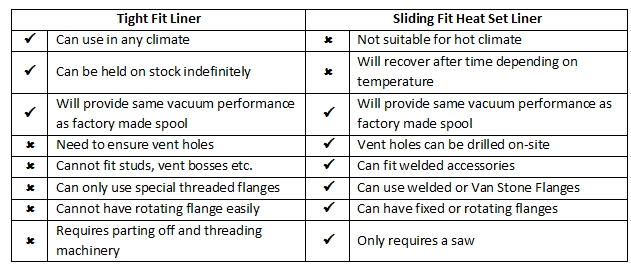

Tight Fit Liner System

A tight fit liner system is manufactured specially for field flare use, because of the need to have vent holes in any spool that is produced as a result of field flaring. It is not possible to drill vent holes on site because of the potential damage to the liner. A spool type is available with vent holes drilled regularly along the length of the pipe to guarantee that any spool made from it has at least one vent hole; our specification ES1067. However, it is possible to use a standard factory finished spool to make a shorter tight fit field flare spool by cutting it up, but it is essential to ensure that there is at least one vent hole in the spool piece to be used.

A key advantage of tight fit liner spools are that they work in all climatic conditions and will provide the same vacuum performance as a factory made spool. The disadvantages are that threaded flanges only can be used in the field, as it is not possible to weld onto the spool with liner inside. Similarly it is not possible to fit lugs, studs, vent bosses or any sort of mounting bracket in the field. Also it is necessary to have a pipe threading and parting off machine in order to prepare the spool for flanging and flaring. CRP manufactures special “companion flanges “for use with these spools which not only provides the correct radius for flaring across at the flange face, but as importantly avoids the potential for a step between the pipe id and the flange id, which can be a stress raiser for the PTFE and cause premature failure.

Sliding Fit Liner System

The sliding fit liner system is manufactured specifically for field flare use and cannot use standard factory spools. Standard factory spools have liners fitted which are an interference fit with the steelwork – this provides support under vacuum conditions. The sliding fit liner is exactly the same as our factory finished spool liner. However, the lined pipe spools go through a special size setting heat treatment cycle, prior to being dispatched. This makes the liner smaller in diameter, allowing them to be removed on site to allow the steelwork to be fabricated and the liner reinserted. This system makes it easier to fabricate spools on site using welded, threaded or Van Stone flanging. Once reinserted the PTFE liner has a tremendous memory and will recover in the presence of heat back to its original diameter to provide vacuum resistance. The key disadvantage of this liner type is that in warm or hot climates – even the UK – the liners will recover over time and become difficult or impossible to remove from the steel pipe.

There are three types of heat set sliding fit liner, varying by their flange configuration. These types are our ES1048 (plain end spool-no flanges), ES1051 (Van Stone flanging one end) and ES1038 (welded stub end with rotating flange). We would recommend having one end flanged (ES1051 or ES1038) as it makes the production of the field flare quicker and less expensive

Summary of Advantages and Disadvantages of Liner Types

Field Flare Equipment

CRP manufactures two styles of field flare equipment, which each have their advantages and disadvantages.

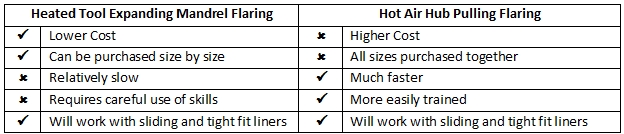

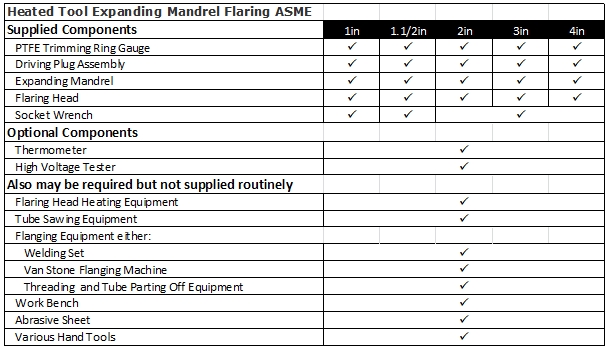

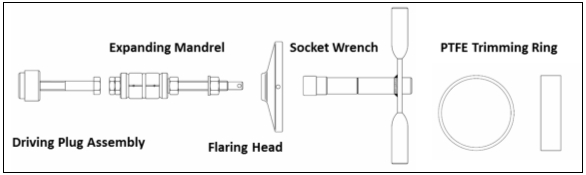

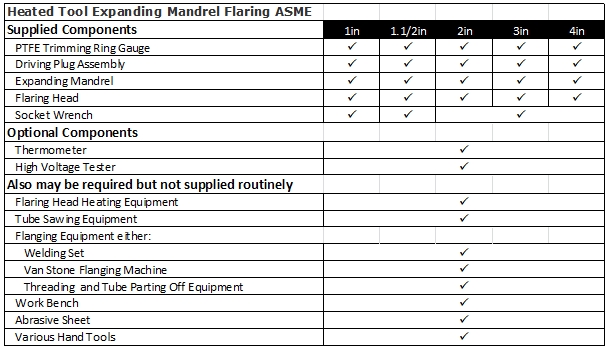

Heated Tool Expanding Mandrel Flaring

This flaring system can work with either tight fit or sliding fit liners. The system works by first inserting an expanding mandrel into the bore of the liner to be flared. This presses the liner out to the inside of the steel pipe and provides a threaded part onto which the tooling can be mounted. The flaring operation is carried out using aluminium flaring heads that have been heated indirectly either using a gas burner or gas torch, electric hot plates, or a gas or electric oven. The flaring heads are supported on the expanding mandrel and are then slowly pressed on to the exposed PTFE allowing the heat from the flaring head to sink into the PTFE and allow it to be flared. The advantage of this type is that it is quite cost-effective in terms of equipment. It is possible to buy individual kits for each nominal bore of 1in, 1.1/2in, 2in, 3in and 4in. It’s disadvantage is that it is not particularly quick in use, but is fine for the production of occasional spools.

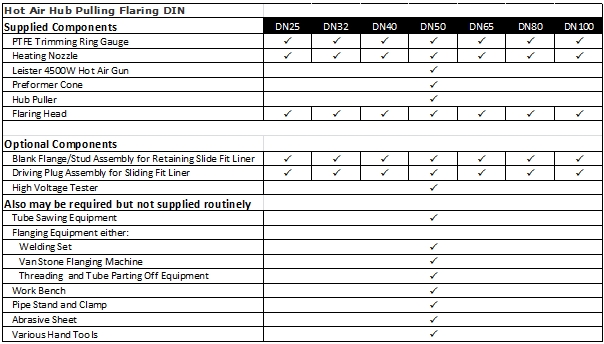

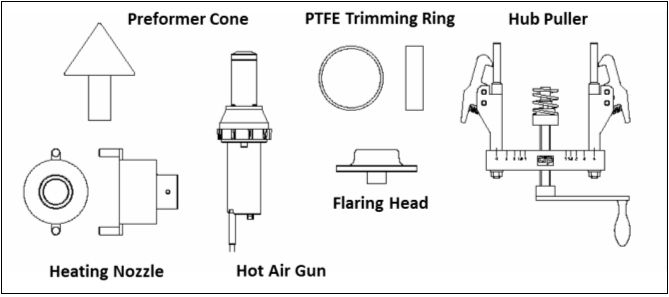

Hot Air Hub Pulling Flaring

This method is designed for working with tight fit liners, but with a small amount of additional tooling can work with sliding fit liners. The flaring operation is carried out by heating the PTFE liner directly using a hot air gun and special heating cones designed to provide the heat at the correct places. Once the liner is heated the flaring is undertaken first by using a hand held cone to push out the liner to around 45 degrees. Then a shaped tool is used, pulled into place using a hub puller mounted on the flange. The key difference is that this method requires the PTFE to be pre-heated to its gel temperature, so requires the hot air equipment. The tooling is cold.

This method has the advantage of being significantly quicker than the heated tool method and less subject to operator error. The equipment is more expensive and is only available as a complete set for 1″ to 4″ or 1″ to 6″NB. It is the ideal method for a customer that wishes to manufacture a significant number of spools efficiently.

Summary of Advantages and Disadvantages of Flaring Methods

Equipment Provided

Training

It is critical that operators are properly trained and to this end we can offer either in house or on-site training for your construction teams. This will ensure the piping is installed correctly and safely on site.