PFA Lined Stainless Steel Tubular Sight Glass

The PFA lined tubular sight glasses CRP manufacture are designed to offer the highest levels of process viewing with a clear Borosilicate Glass tube offering 360 degree viewing. The glass is of a heavy wall construction up to 9mm thick and depending on nominal bore the sight glasses can be used in corrosive processes up to 10 barg and 150 degrees C. The flange ends of the sight glasses have HiPerFlon PFA linings and are manufactured from stainless steel for external or marine environments etc. We can supply flanges to suit ASME 150 or DIN PN10 and PN16. The choice of materials ensures that the sight glass will provide long service life conveying acids and other highly corrosive medias. Where the glass may be subjected to attack from for example hydrofluoric acid, we can supply the sight glass internally lined with an FEP sleeve. We would recommend that all our sight glasses are supplied with an outer acrylic shield to help prevent mechanical damage of the glass from external elements.

We offer a standard length of sight glass equivalent to the Atomac AKH2 valve in length. We call this our CTSG Tubular Sight Glass. We can supply all sizes of sight glasses in shorter or longer lengths up to 1500mm, we call these with a special length DTSG Tubular Sight Glasses.

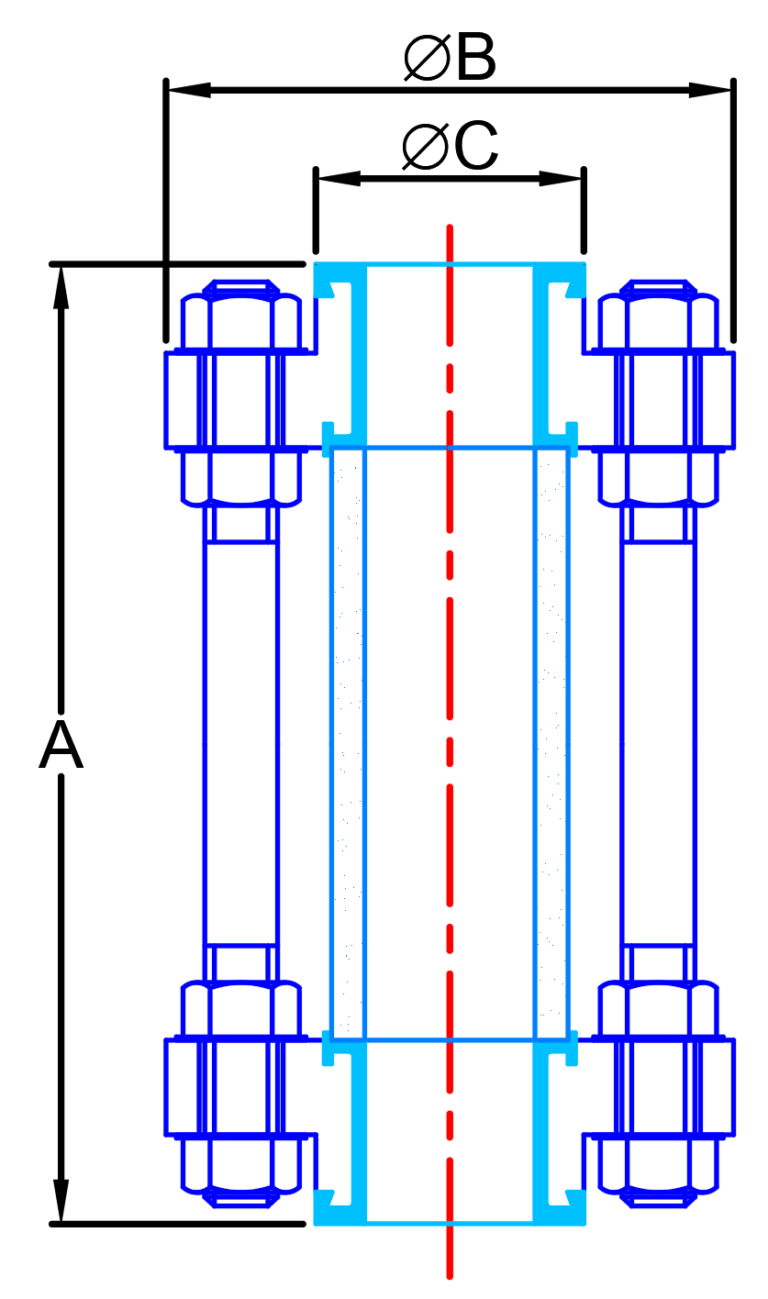

Dimensions below are for the standard CTSG Tubular Sight Glass available to suit both ASME 150 and DIN PN10/16 flanges to EN558-1 basic series 1.

| Dimensions | |||||||

|---|---|---|---|---|---|---|---|

| To Suit Pipework | Face – Face | Flange ø | Raised Face ø | Weight 500mm lg. | Glass | ||

| ASME 150 Flanged Piping Systems | |||||||

| Inches | mm | Dim. A mm | Dim. B mm | Dim. C mm | Kg. | ø mm | Wall mm |

| 1 | 25 | 152 | 110 | 51 | 3.7 | 30 | 4.5 |

| 1 1/2 | 40 | 178 | 125 | 73 | 5.1 | 50 | 7.0 |

| 2 | 50 | 203 | 150 | 92 | 7.5 | 60 | 9.0 |

| 3 | 80 | 241 | 190 | 127 | 13.2 | 90 | 9.0 |

| 4 | 100 | 292 | 230 | 157 | 18.5 | 120 | 9.0 |

| 6 | 150 | 356 | 280 | 216 | 25.6 | 170 | 9.0 |

| 8 | 200 | 300 | 345 | 270 | 40.1 | 215 | 9.0 |

| 10 | 250 | 300 | 405 | 324 | 48.2 | 300 | 9.0 |

| 12 | 300 | 300 | 485 | 381 | 76.7 | 325 | 9.0 |

| DIN PN 10/16 Flanged Piping Systems | |||||||

| 1 | 25 | 160 | 115 | 68 | 3.8 | 30 | 4.5 |

| 1 1/2 | 40 | 200 | 150 | 88 | 5.5 | 50 | 7.0 |

| 2 | 50 | 230 | 165 | 102 | 8.3 | 60 | 9.0 |

| 3 | 80 | 310 | 200 | 138 | 12.0 | 90 | 9.0 |

| 4 | 100 | 350 | 220 | 158 | 18.5 | 120 | 9.0 |

| 6 | 150 | 480 | 285 | 212 | 29.3 | 170 | 9.0 |

| 8 | 200 | 300 | 340 | 268 | 40.1 | 215 | 9.0 |

| 10 | 250 | 300 | 395/405 | 320 | 48.2 | 300 | 9.0 |

| 12 | 300 | 300 | 445/460 | 370/378 | 76.7 | 325 | 9.0 |