Stainless Steel Lined Piping Systems

Stainless steel lined piping has many advantages over carbon steel lined pipe.

There is no requirement for any preparation of substrate and over coating of steel to prevent corrosion.

Unlike painted steel, stainless steel does not need to be inspected for paint deterioration, it does not require repainting, saving time and money on plant shut downs, scaffolding, removal of insulation, removal of paint and subsequent repainting.

The stainless steel piping matches well aesthetically around the heads of Hastelloy vessels keeping the plant looking uniform.

As there is no possibility of paint to flake or chip, process contamination can be kept to a minimum, ideal in final stage processes or where the piping is regularly broken down for inspection, cleaning and revalidation.

For use where the environment is itself corrosive like coastal, off shore or underground stainless steel has many advantages over carbon steel in resisting external corrosion.

CRP recommend utilising Van Stone flanged pipe spools as elimination of welds and stub ends gives significant cost savings over welded fabrications. We aim to carry stock of stainless steel pipe and flanges so we can rapidly produce lined stainless steel pipe spools by this method. We can of course supply welded construction pipe spools if required, still in remarkably short lead times.

All our piping and fittings range can be supplied in lined stainless steel, please contact the sales team for further information or a quotation.

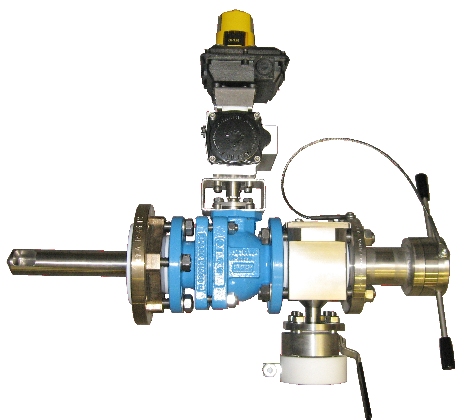

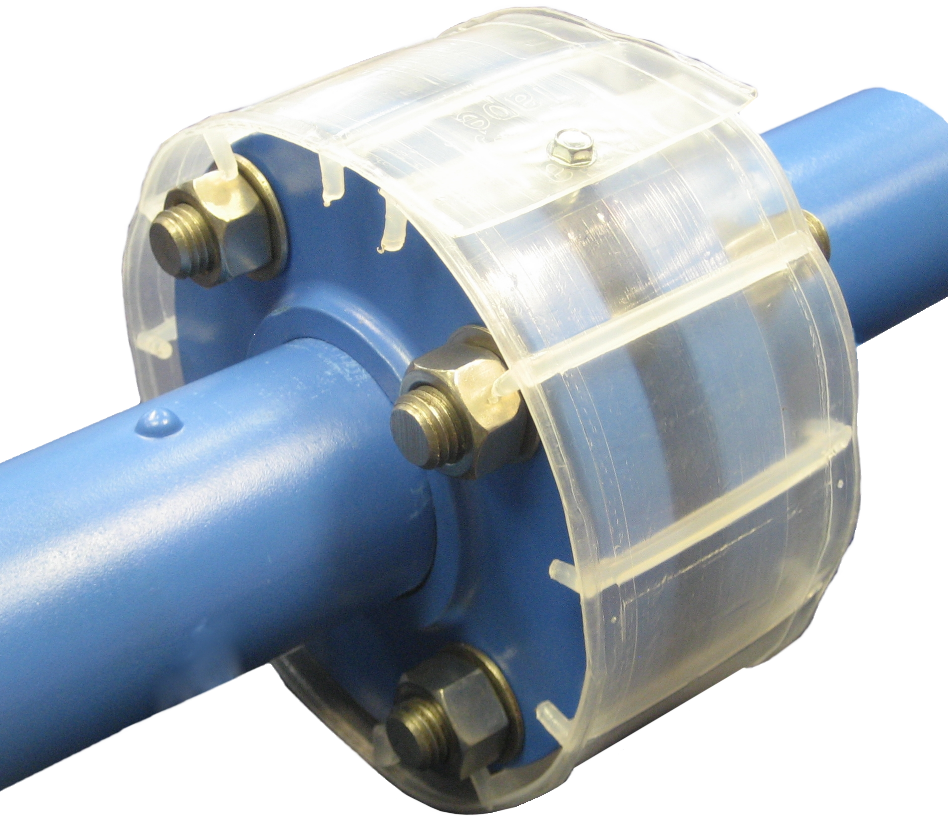

To compliment the stainless steel PTFE lined piping we also offer PFA lined stainless steel ball valves, stainless steel poppet check valves and sight glasses. This enables us to offer a complete system with all wetted parts in HiPerFlon PTFE / PFA but having a stainless steel external finish.

Our standard stainless steel piping is supplied with mill finish but we are able to supplied polished piping if required.

However stainless steel material is reacting critical with Chlorine ions and stress corrosion cracking should be considered in these situations.