Introduction to Certification

CRP uses several procedures to maintain traceability of materials and tests conducted on our products, all documented in our ISO9001:2015 QMS. Various levels of conformance certificates can be issued to our customers.

Our philosophy is to keep records of materials and tests of the key materials – the fluoropolymers linings. In all of our years experience we have never received a failure accountable to the steelwork. The linings are the only wetted parts and these materials are the critical parts that need to have a maintained traceability system. We issue as standard certificates of conformity type 2.2 and record and hold all material and test records on the linings used. If in the future there is found to be any problems we can refer from the hard stampings on the steelwork back to the exact batch and test records of the liners. Because of this we believe it is a costly and unnecessary exercise to supply the 3.1 material certificates with the goods.

Why have certificates of conformity?

Customers are keen to have suppliers confirm, in writing, the quality of goods supplied and the materials from which they are produced.

Validation of quality provided through the C of C “statement” is meant to give:

a) A declaration, in writing, that the goods are as ordered, and therefore are meant to give a degree of confidence that they are fit for purpose.

b) The confidence to reduce or dispense with goods inward inspection.

c) Traceability, provided via test results on documents such as 3.1 material certificates.

CRP supply certificates of conformity conforming to the standard BS EN10204 – METALLIC PRODUCTS – TYPES OF INSPECTION DOCUMENTS. Whilst our products contain non metallic fluoropolymers liners we still use this widely accepted industry standard. This standard supports seven different levels of certification. CRP has adopted two of the most suitable of these- types ‘2.2 Test Report’ and ‘3.1 Inspection Certificate’.

EN 10204 Type 2.2 Test Report is a document which:

a) Certifies that the items supplied are in compliance with the requirements of the order.

b) Details test results based on non-specific inspection and testing. This means that the products inspected and tested may not necessarily be the product actually supplied, and is more a verification of the process rather than the product.

c) Can be validated or signed by delegates responsible for producing the report.

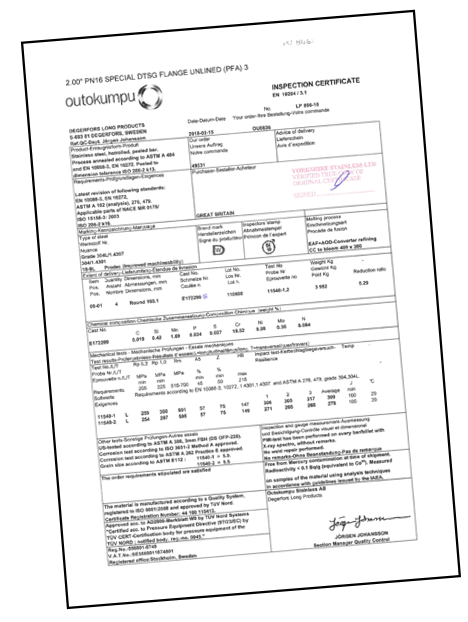

EN 10204 Type 3.1 Inspection Certificate is a document which:

a) Is issued by an authority, which is independent of manufacturing. (QA Department)

b) Details specific results of inspection and testing necessary to meet the requirements of the order. This means that the products referred to as being inspected and tested are the actual items supplied and is a verification of the products and the process.

c) Must be signed by the person responsible for document validation. (QA Department)

CRP supply Type 2.2 test reports as standard with all our products, this lists the actual inspections and tests carried out on each component on the report.

We can supply Type 3.1 Inspection Certificates (Material or Mill certificates) with just about all of our products, however the compiling of these certificates can take considerable man hours, certificates are required from our suppliers and their subsequent suppliers etc. Due to this there is a cost which needs to be considered for this service. Often too, additional batch recording and hard stamping of steelwork needs to be done as the items are manufactured, for this reason we must know that EN10204 type 3.1 material certificates are required at time of order for steelwork components as we cannot supply t

hem retrospectively at a later date. Of course through our standard manufacturing procedures we are always able to track back and trace the original lining polymer batches and tests to help with any investigations.

Traceability

Traceability of products and/or materials is meant to help any investigation into “what went wrong”, in the event of a problem, through the recording and storing of relevant details for future reference.

Levels of traceability can be very precise, down to the exact time of manufacture, from the most detailed chemical properties of materials, to the inspection, testing and subsequent acceptability of assemblies. Levels need not be this precise. It may be sufficient to record, in what year a product was manufactured, or whether it was produced before or after a certain batch of material was used.

Some manufacturers choose to save on the cost of providing the means to produce absolute traceability, by doing only the basic essentials. This can be costly during investigation, but overall may be economical, depending on the frequency of the exercise.

The extent or levels of implementation are dependant on an estimation of the criticality of the products and the cost of collating and archiving records, balanced against the likelihood of future product failure and resultant consequences.

Traceability is not a single direction activity and, if managed well, will provide any investigation with the means to trace through production, inspection and test records of items, from end user to source supplier or vice versa.

Further information on our standard test and traceability procedures on our PTFE and PFA liners can be found here.