Sampling Systems

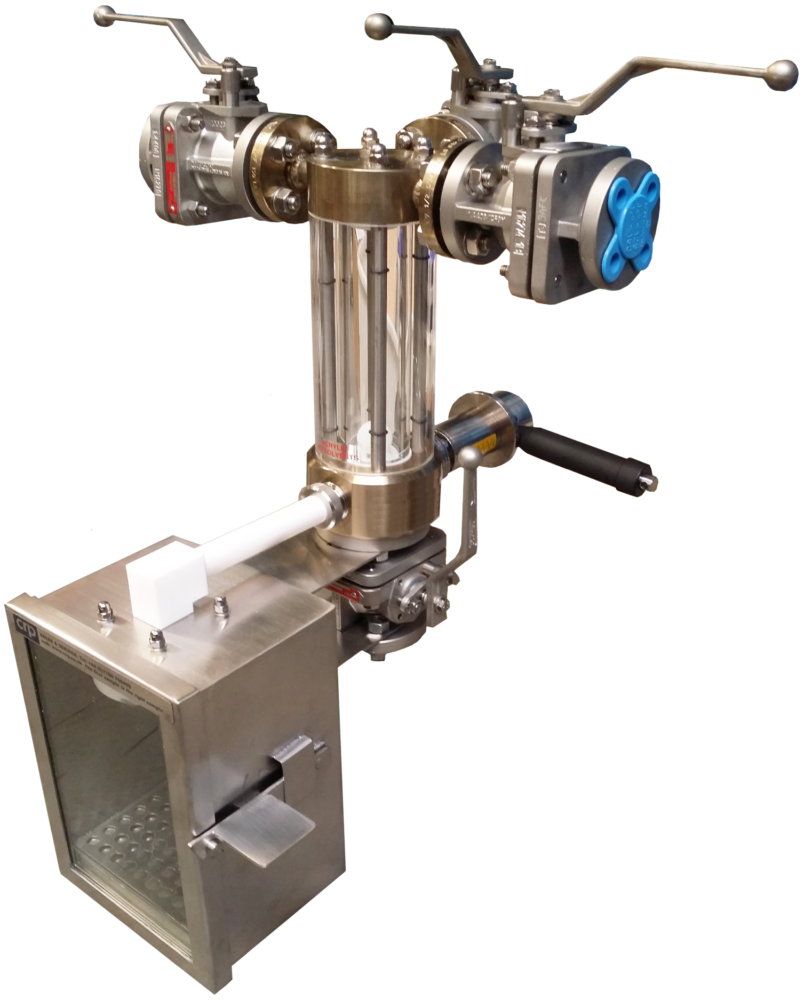

CRP design and manufacture a wide range of Sampling Valves and Systems for sampling chemicals.

From simple inline samplers, to recirculating vessel sampling systems and bespoke samplers. All providing safe sample dispensing of potentially toxic or corrosive media, safeguarding the operator and the environment.

Download Catalogue