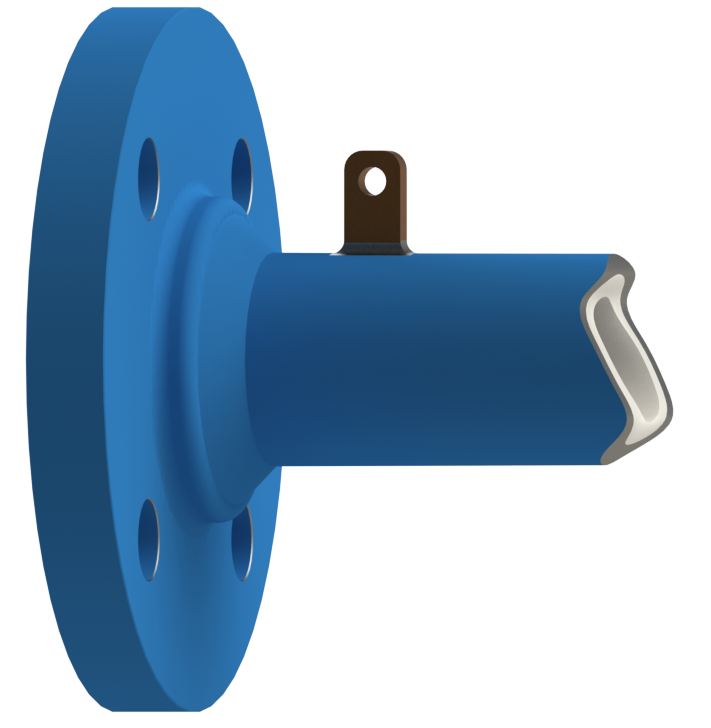

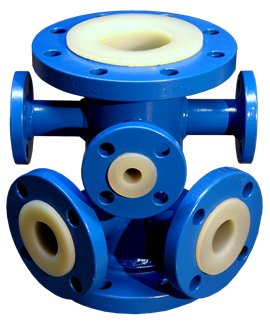

Lined Piping

Hiperflon® lined piping and fittings from CRP are produced with second generation paste extruded PTFE linings and PFA moulded fittings using raw materials manufactured from the latest PFAO free catalyst processes.

Download Catalogue

Hiperflon® lined piping and fittings from CRP are produced with second generation paste extruded PTFE linings and PFA moulded fittings using raw materials manufactured from the latest PFAO free catalyst processes.

Read more

Read more

Read more

Read more

Read more

Read more

Read more

Read more

Read more

Read more