Valves

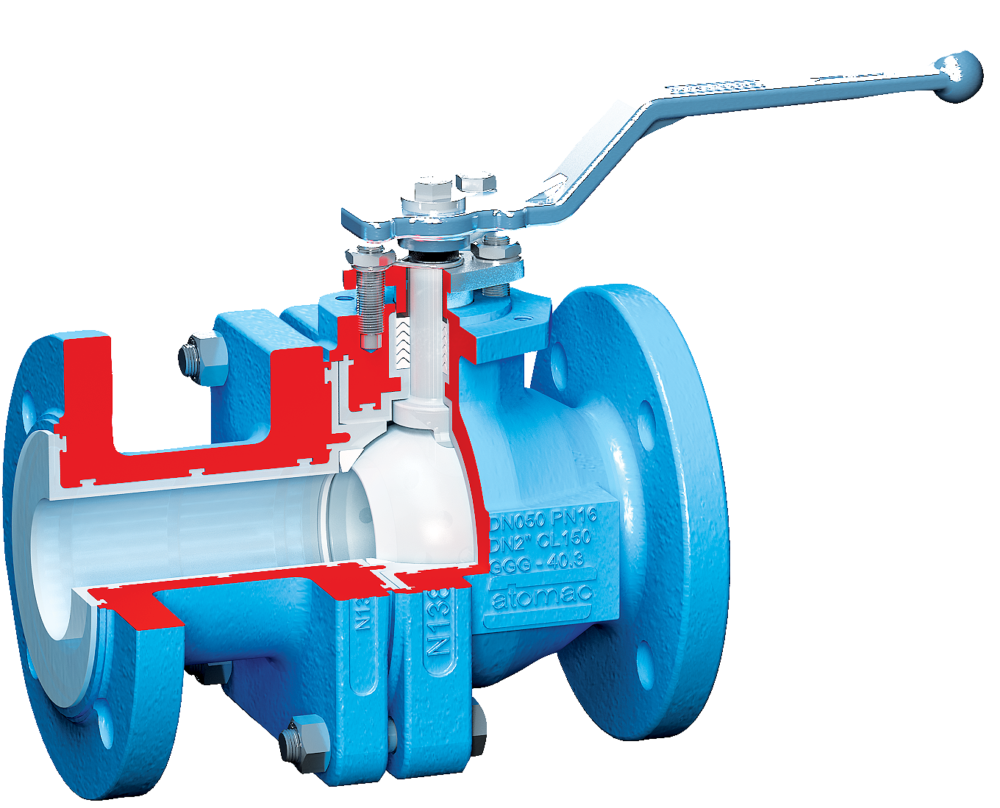

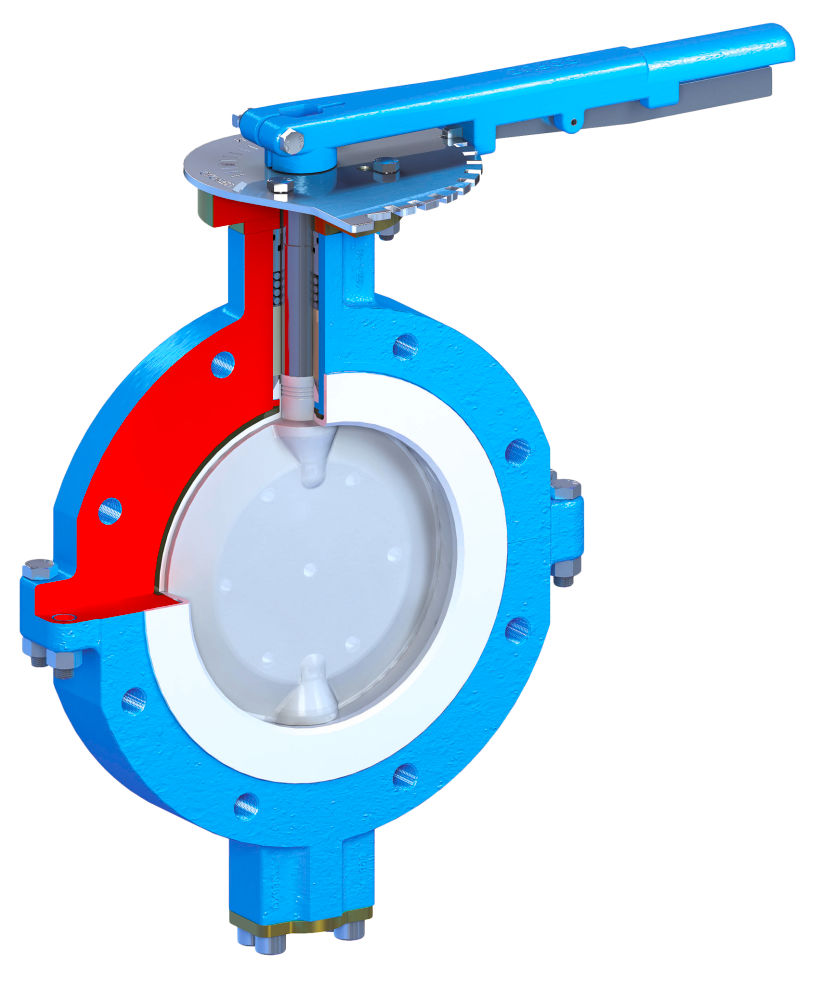

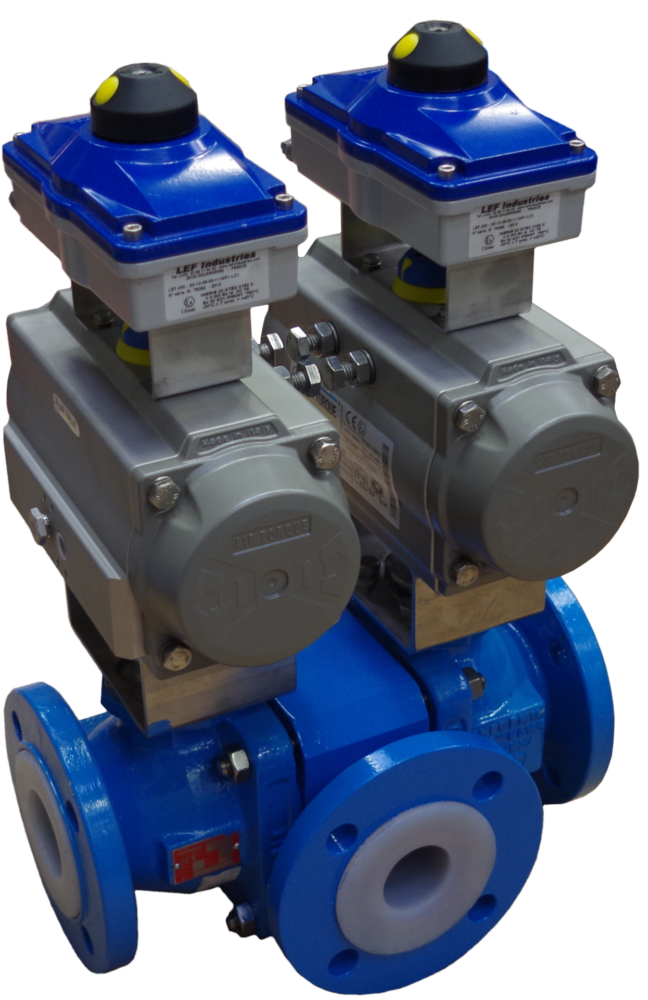

We have a wide portfolio of valves which are all designed with performance forefront, we are the UK distributor of the market leading Atomac range of PFA lined ball, check and plug valves. The Durco range of PTFE / PFA lined butterfly valves and sleeve-line non lubricate plug valves. We also manufacture our FluoroFlow range of PFA lined poppet check and swing check valves.

All the valves we consider are technically superior to provide long trouble free operation in our customers processes which we know can be the most corrosive and demanding and warrant the very best products available.