CRP recently exhibited at Chem UK at the NEC on the 15th and 16th of May with support from our key partners, SGL and CP pump systems.

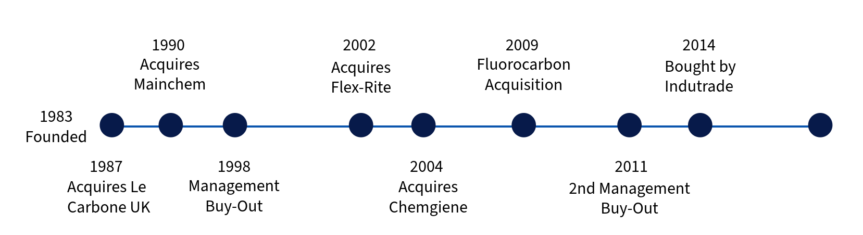

Corrosion Resistant Products Ltd (CRP) – a leading manufacturer and stockist of high-quality Fluoropolymer PTFE/PFA-lined piping and equipment, in Littleborough, North Manchester. Founded in 1983 we’re at the heart of developing reliable and cutting-edge solutions for industries that handle the most challenging chemicals, such as the chemical and pharmaceutical sectors.

At CRP, we don’t just produce piping systems; we engineer safety, reliability, and quality into every product we create.

Quality

We’re passionate about quality, ensuring our piping solutions offer the longest service life, the lowest total cost of ownership, and the highest performance standards. By manufacturing with advanced materials like modified PTFE and PFA, we guarantee that our products stand up to even the harshest environments.

Innovation

CRP thrives on innovation and problem-solving. We work closely with our customers, tailoring solutions to their specific needs—no matter how complex. But we don’t stop there; we want our customers to succeed and stay safe, so we provide ongoing support through in-person training, webinars, and online resources, sharing knowledge from our industry experts to make sure everyone on-site is confident in maintaining their systems.

Timeline

Indutrade

Since 2014, we’ve been proud to be part of the Indutrade group – a global network of innovative companies. This connection gives us unique access to worldwide expertise, resources, and opportunities for collaboration.

- Head Office Sweden

- Turnover

- Allows us to be connected to 200 companies in 26 countries- Global presence.

- 4,418 employees

- A unique approach, sharing expertise.

Learn about flange guards, their importance, types, installation, maintenance, benefits, and applications in the industrial sector. Read More…