Heat Exchangers

Often samples are taken from processes at high temperatures, anything above 60° C could be considered as a risk to the operator. The sample can be left to cool in situ before being handled but we would recommend that the sampler is supplied with a cooler to bring the temperature to safe levels. We have two designs of heat exchanger we can offer, with both types completely isolating the sample liquid from the cooling liquid.

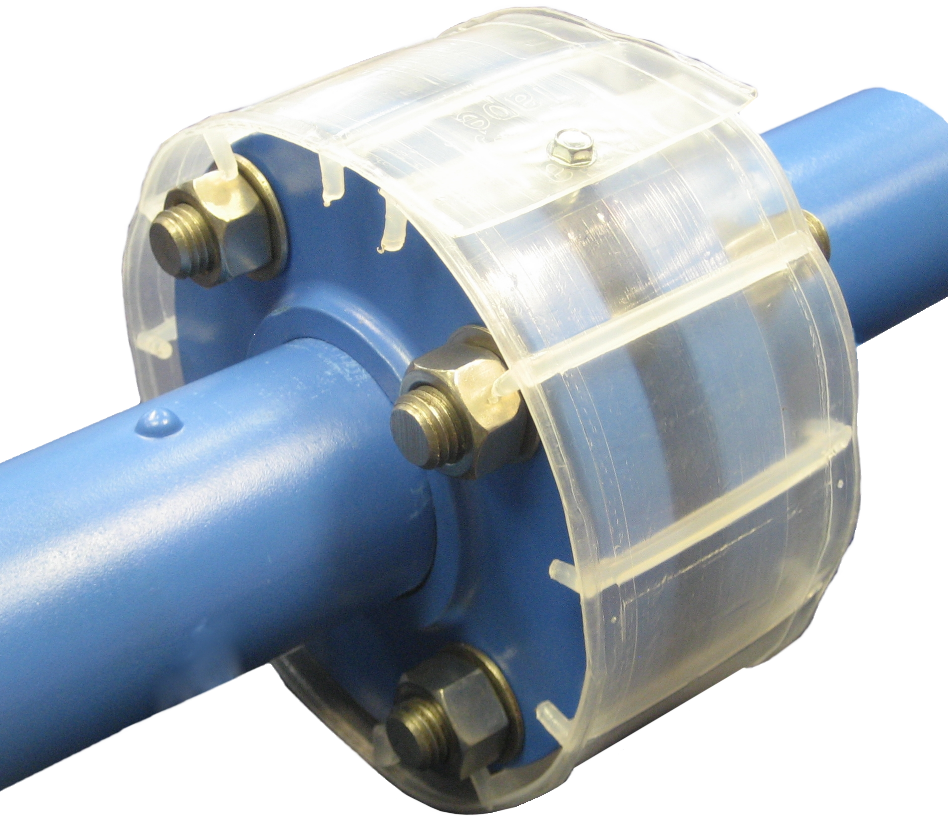

Coil Heat Exchanger

This heat exchanger utilises a small bore tube through which the sample flows into the chosen sample dispensing method. This tube is coiled and positioned within a cylindrical water jacket, the cylinder has a water inlet and outlet which should be connected on site to a cold running water source. As the cold running water passes over the coil the heat is drawn from the sample. The cooling water supply need only be flowing when a sample is going to be taken, typically only around 10 seconds. The standard unit can reduce the sample temperature by 100° C depending on sample flow rates. For higher temperature drops larger heat exchangers can be supplied.

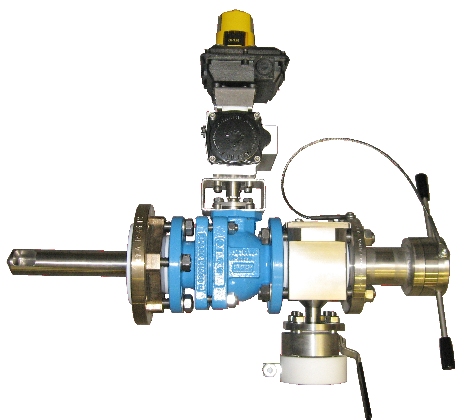

Volumetric Heat Exchanger

This heat exchanger utilises a fixed volume sample holding cylinder. The sample is dispensed from the sample valve into the cylinder. The cylinder has an outer cooling jacket which has water inlet and outlets to connect to a running cold water source. The sample is then released from the cooling cylinder into the sample bottle using a ball valve.

The heat exchanger can be manufactured from Hastelloy components for corrosive processes. The design also lends itself to remote processes where it is not possible to use cooling water. The sample can still be taken from the process pipeline in the normal way and held in the volumetric cooler. The sample can be left within the cooling chamber to cool naturally. This is often achieved very quickly due to the large metal content of the heat exchanger quickly drawing the high temperature away from the contained sample.